Plastic Injection Mould Making Process and Customer Support

Welcome to Al Barsha Precision Moulding Dies (BPTUAE), where precision, expertise, and customer care drive our creation of high-quality injection moulds for diverse industries. We ensure that each mould meets exact specifications and delivers reliable, high-performing plastic components.

Injection Mould Manufacturing Process

Planning and Prototyping

- Strategic Planning: We begin by thoroughly understanding the client’s requirements, focusing on the intended functionality and design specifics of the product. Our expert team collaborates closely with clients to ensure that the mould design aligns perfectly with project needs and quality standards.

- Prototyping: After the initial planning, we develop accurate prototypes that help visualize and verify the mould design. This step allows us to assess each aspect of the design and make necessary adjustments before full-scale production, ensuring the final mould meets all project requirements.

Precision Mould Manufacturing

- Material Selection: We select high-quality, durable materials such as hardened steel or aluminum, suited to withstand the demands of injection moulding. These robust materials ensure the mould retains precision and quality, essential for producing consistent, high-quality outputs over time.

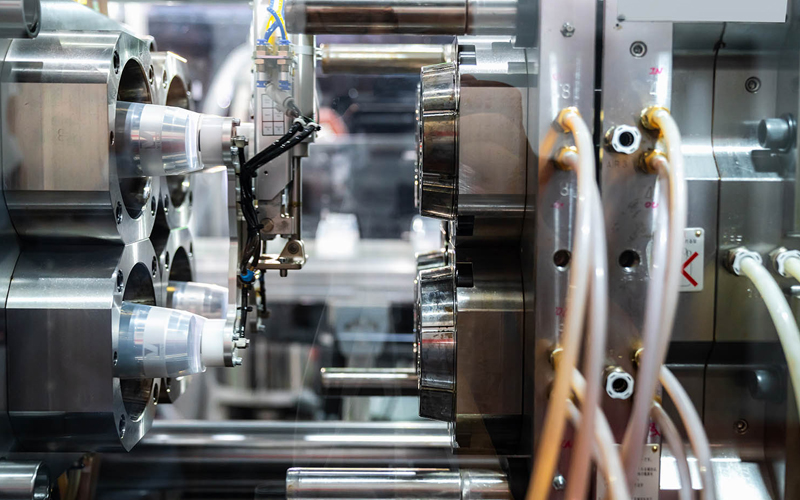

- CNC Machining: Using advanced CNC (Computer Numerical Control) machining, we achieve the intricate details and fine tolerances crucial for high-quality moulds. Our precise machining techniques allow us to meet strict design specifications, creating moulds capable of producing components with complex features and reliable quality.

- Assembly & Testing: Once machining is complete, we meticulously assemble all components, ensuring a precise fit and alignment. We then conduct rigorous testing to confirm that each mould operates flawlessly and meets all specifications, ensuring durability, accuracy, and reliability.

Material Preparation

- Resin Compatibility: To achieve optimal performance, we select and condition thermoplastics based on the specific application. This preparation includes assessing the material’s compatibility with the product’s requirements, ensuring longevity and performance consistency.

- Color Matching: Where needed, we customize color finishes to meet exact client specifications, providing consistent branding or aesthetic results with high-quality, color-accurate moulded products.

Delivery and Support

Our commitment to excellence extends beyond production, with a focus on seamless delivery and comprehensive support.

- Timely Delivery: We understand the importance of deadlines in manufacturing. Through careful planning and efficient logistics, we ensure that every mould is delivered on time, keeping projects on schedule without compromising quality.

- Comprehensive Technical Support: Our support doesn’t end with delivery. After manufacturing, we provide ongoing technical assistance, including setup, maintenance, and troubleshooting to ensure the mould operates at peak performance. Our team is always ready to address any questions or challenges.

- Customer Satisfaction and Long-Term Partnerships: Customer satisfaction is fundamental to our approach. By exceeding expectations and supporting clients at every stage, we foster long-term partnerships built on trust and reliability. From initial consultation to delivery and aftercare, Al Barsha Precision Moulding Dies is dedicated to being a dependable partner for all your mould-making needs.

At Al Barsha Precision Moulding Dies, our expertise in mould manufacturing is matched by our dedication to customer care. Contact us today to discover how our comprehensive solutions can support your project with precision, reliability, and exceptional service.